Process

Flaking process

The process steps

-

Hydrothermal treatment

-

Production of grain flakes

-

Drying and cooling

-

Final sieving

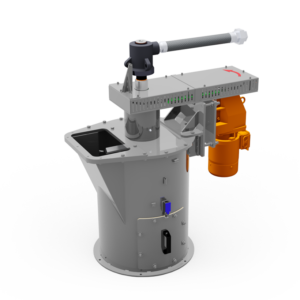

Round steamer type RD 500 V2

Hydrothermal treatment

During the steaming process, a hollow shaft stirring the product which is fitted with steam nozzles is used to evenly inject steam directly into the product. This prepares the kernels for processing in the roller mill. The homogeneous penetration of the product all the way to the core is essential for the quality of the flakes.

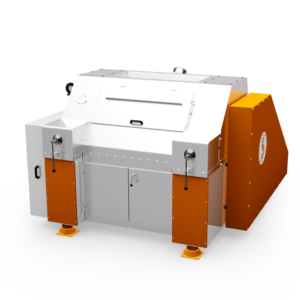

Flaking roller mill type FWS

Production of grain flakes

The product to be flaked is evenly distributed over the entire width of the rollers. The high hydraulic compacting pressure and a precise roller setting ensure consistent quality while also delivering high performance.

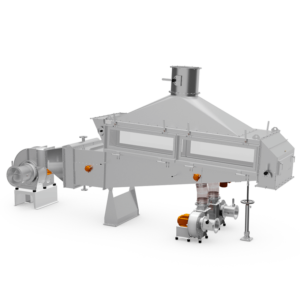

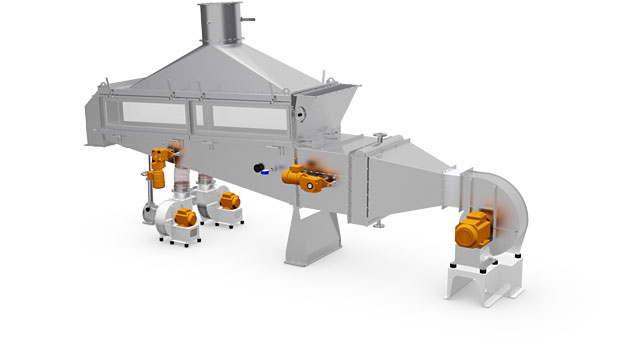

Fluid-bed dryer type WST

Drying and cooling

After the flaking roller mill, hot air is passed through the warm and damp flakes to dry them and achieve the desired final moisture content, after which they are cooled down using cold air.

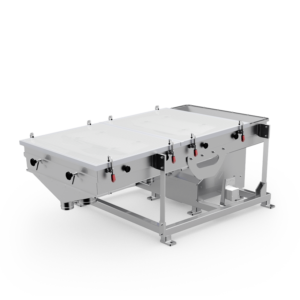

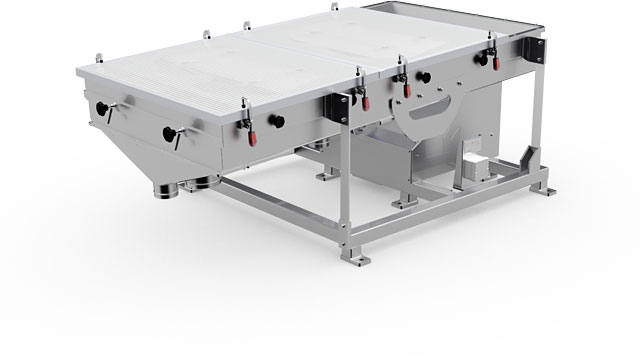

Control sieve type KS

Final sieving

The control sieving is performed using two different sieves arranged in series which are installed over a trough with a slight inclination. They separate fine parts, the final product, and overly large pieces from each other.