Paddy table type HTA

For reliable final inspection of hulling results

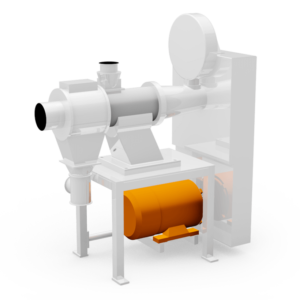

The paddy table is utilised in the sorting area after hulling. It filters out unhulled kernels from homogenous grain batches and guarantees a perfect final result.

Weighing the results

After the hulling process, the paddy table is responsible for resorting. In its feed trough, the grain to be sorted is distributed evenly to the chambers of the machine – uniform lifting motions separate the kernels according to their specific weight. In this manner, unhulled kernels can reliably be sorted out.

Classification chambers

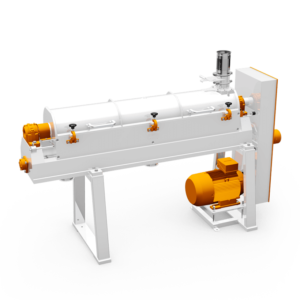

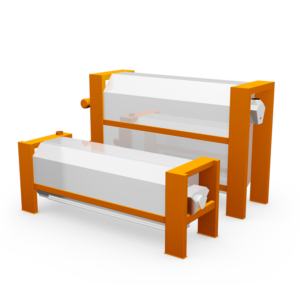

Depending on the version of the paddy table, it contains between 24 and 60 sorting chambers. Due to reasons of hygiene and wear, the product decks of the individual chambers are made of rustproof stainless steel. The inclination and rotational speed can easily and individually be adjusted to the respective product: for example, a three-point stroke adjustment allows for preselection of the individual lift stroke length.

At a glance

-

Ideal for resorting at the end of the hulling process

-

Lower frame features a robust welded design with reinforced steel plates for particularly quiet running

-

Innovative feed trough design for even distribution to the chambers

-

Optimised leakage air supply in inlet area

-

Suitable for the following grains: Oats, millet, sunflower seeds, spelt

But that's not all the paddy table can do for you

The paddy table achieves the best results when the grain is particularly homogeneous. Hence, it is recommended that a length sorter be placed before the paddy table so that the unsorted product is as well-prepared as possible.

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an