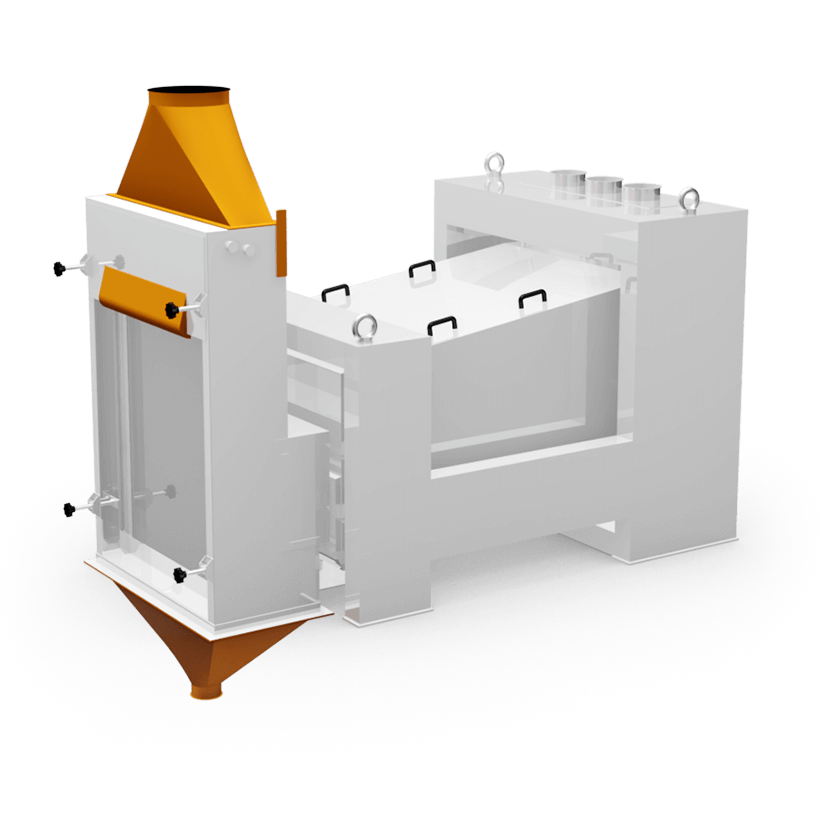

Cleaning machine type GPA 10

One sieving system for all cases

This multi-functional cleaning and control sieve takes care of the sieving of foreign material and overly large or small particles – while maintaining the same precise separation threshold.

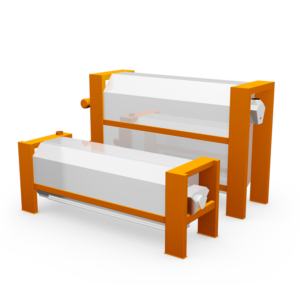

Flexible and robust

The freely oscillating sieving tray of the sieving machine is attached to a solid supporting structure which guarantees an almost maintenance-free continuous operation of the machine. The oscillating movement of the sieve guarantees efficient sieving. The use of the entire open sieve surface is ensured by the self-cleaning principle of the screen plates via the tried-and-tested rubber sphere cleaning mechanism.

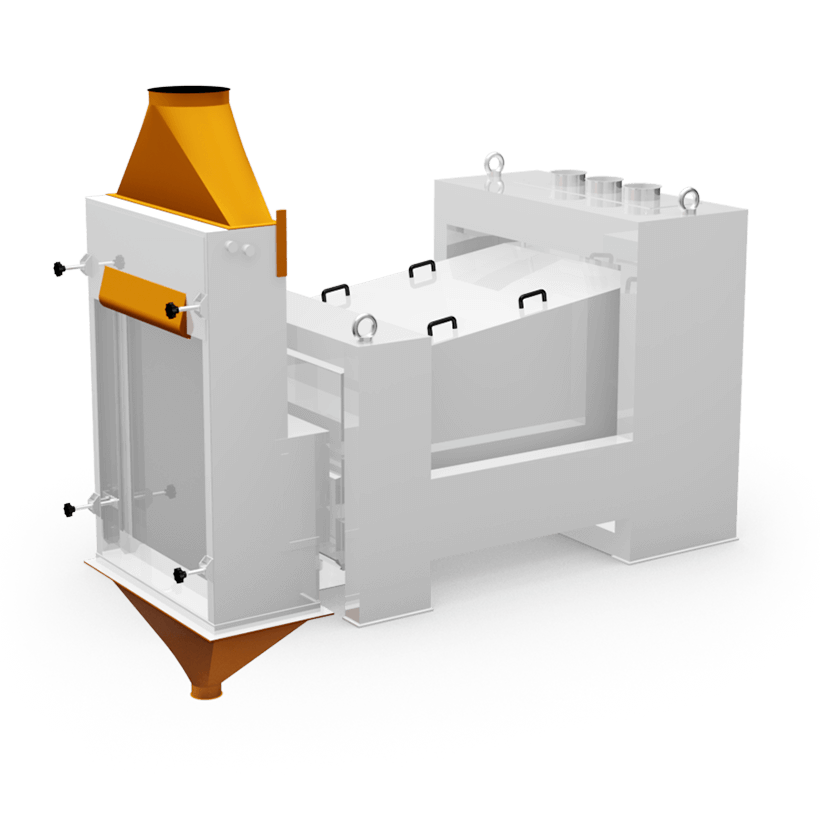

Three square meters of sieve surface

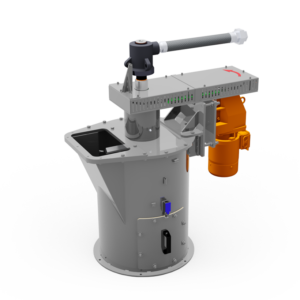

Firstly, the product enters the pre-sieving layer, which removes coarse particles and stones. On the main sieve, small kernels, seeds, and sand are separated. Finally, a high-performance outlet extraction system with a highly configurable separation threshold ensures a clean result during the aspiration of the product. Should the sieve need to be swapped out, this can be done quickly and easily via a maintenance hatch on the front.

At a glance

-

Multi-functional cleaning and control sieve

-

Designed for maintenance-free continuous operation

-

Screen plates available in stainless steel

-

Self-cleaning via oil- and grease-resistant rubber spheres

-

High-performance outlet aspirator

-

Easy sieve changes

-

Suitable for the following grains: Oats, wheat, barley, spelt, legumes, etc.

But that's not all the sieving machine type GPA can do for you

In addition to cleaning and control sieving, the machine can also be used for classification.

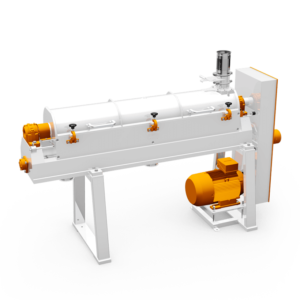

Technical data

-

Gewicht

1100 kg

1300 kg -

Antrieb

0.75 kW

0.75 / 0.55 kW -

Maße

2426 x 1426 x 2400

2950 x 1426 x 2925

Download data sheet

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an