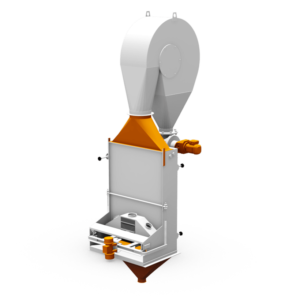

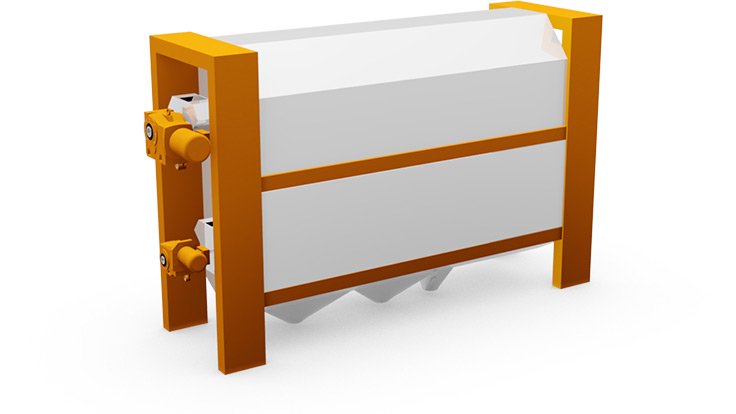

Indent cylinder type ETA / DTA / 2DTA

Whether short or long

The indent cylinder plays an important role both in grain cleaning as well as in sorting. The reliable classification of grain according to length is its greatest talent.

So simple, yet so ingenious

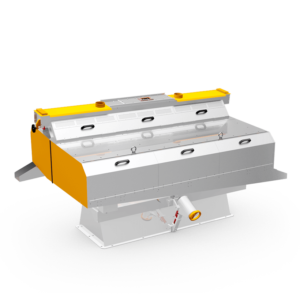

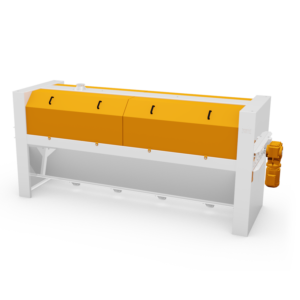

The completely encased machine consists of a self-supporting steel frame structure which holds the indent cylinder. The working cylinder consists of two half steel drums in which precisely embossed tear-shaped dents guarantee meticulous product separation. All small particles are lifted into an inclination-adjustable trough and transported out of the machine via a conveying screw.

Reliability that lasts decades

When used for cleaning, the indent cylinder separates the product e.g. from weed seeds, foreign grains, and unwanted long grains. During sorting, it separates according to length: e.g. cut kernels from uncut ones, or hulled from unhulled oats.

At a glance

-

Reliable cleaning or sorting by length

-

Easy assembly thanks to special sheet steel screening drums in split version

-

Depression adjustment via robust handwheel with intuitive position scale

-

Integrated discharge hood with sample-taking port and rubber covers

-

Suitable for the following grains: Rice, oats, millet, buckwheat, peas, barley

But that's not all the indent cylinder can do for you

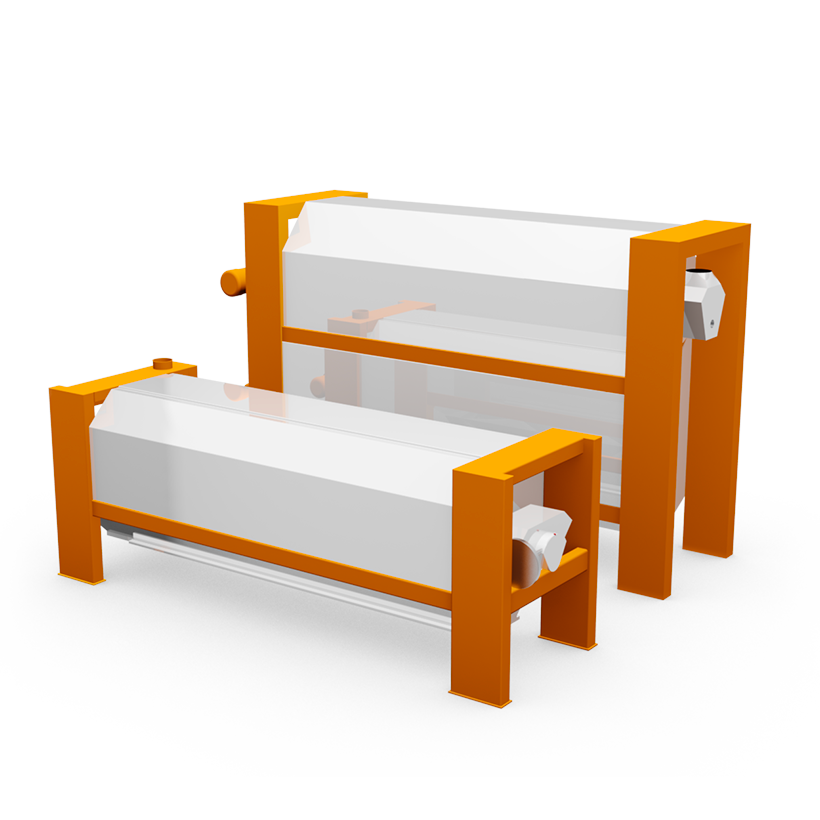

The double indent cylinder version allows for resorting of the product screened in the first indent cylinder. A subsequent integrated length and thickness sorting system allows for generous cleaning and for the recovery of small oat kernels that were sorted out.

Technical data – DTA

-

Gewicht

1450 kg

1790 kg

1640 kg

2230 kg

2090 kg

2330 kg

2480 kg -

Antrieb

1.1 / 0.55 kW

1.5 / 1.1 kW

1.5 / 0.55 kW

2.2 / 1.1 kW

3.0 / 0.55 kW

3.0 / 0.55 kW

3.0 / 1.1 kW

-

Maße

2924 x 978 x 2115

3398 x 985 x 2080

3430 x 979 x 2115

3898 x 985 x 2080

3938 x 986 x 2132

4898 x 965 x 2080

4898 x 985 x 2080

Technical data – 2DTA

-

Gewicht

1640 kg

3640 kg -

Antrieb

3.0 / 0.55 kW

1.5 / 0.55 kW -

Maße

5200 x 986 x 3002

3700 x 986 x 3002

Download data sheet – 2DTA

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an