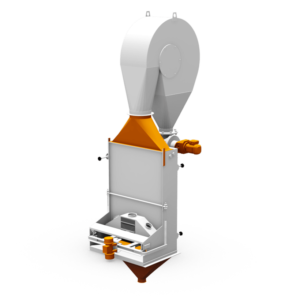

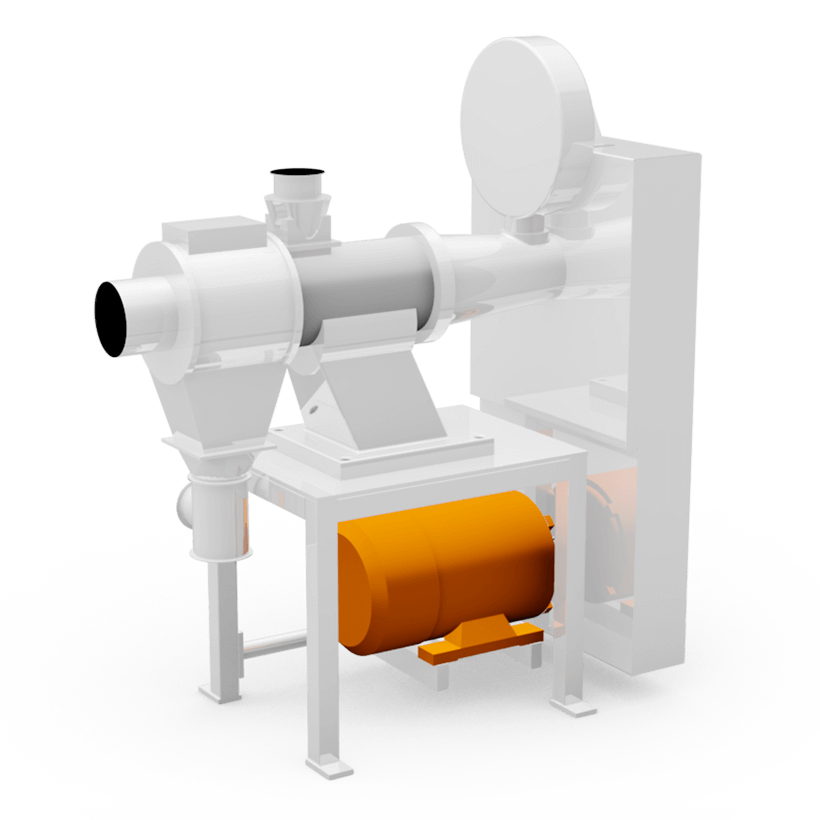

Jet-Pearler type JP 1

Gentle conditioning or effective hulling

During friction processing, i.e. rubbing against the screen plates and grains chafing against each other, the grain is gently cooled via a stream of air.

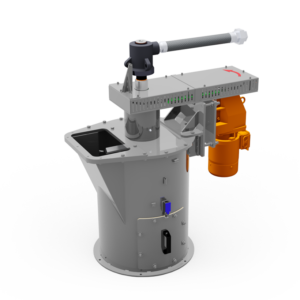

Custom hulling setting

The Jet-Pearler is equipped with a rotor with integrated perforated basked, a feed screw, and a weight-loaded outlet hatch. The movable weight on the weight lifted flap determines the intensity and retention time of the processing.

Constant cooling

Via an integrated fan, the product is constantly being cooled during the processing. The aspiration takes place below the perforated basket, such that the dust generated through abrasion that manages to pass through the sieve perforation is also extracted.

At a glance

-

Gentle hulling with constant air cooling

-

Custom intensity for surface processing of product

-

Robust perforated basket for easily changing the screen plates

-

Suitable for the following grains: Oats, hemp, millet, quinoa

But that's not all the Jet-Pearler can do for you

The machine can be used both for preparation i.e. for grinding down a product for further processing, as well as for purposes such as the milled-hulling of problematic grain. Furthermore, the intensity of the surface processing can also be configured via the sieves selected.

Technical data

-

Gewicht

480 kg

-

Antrieb

11 kW

-

Maße

1386 x 620 x 1489

Download data sheet

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an