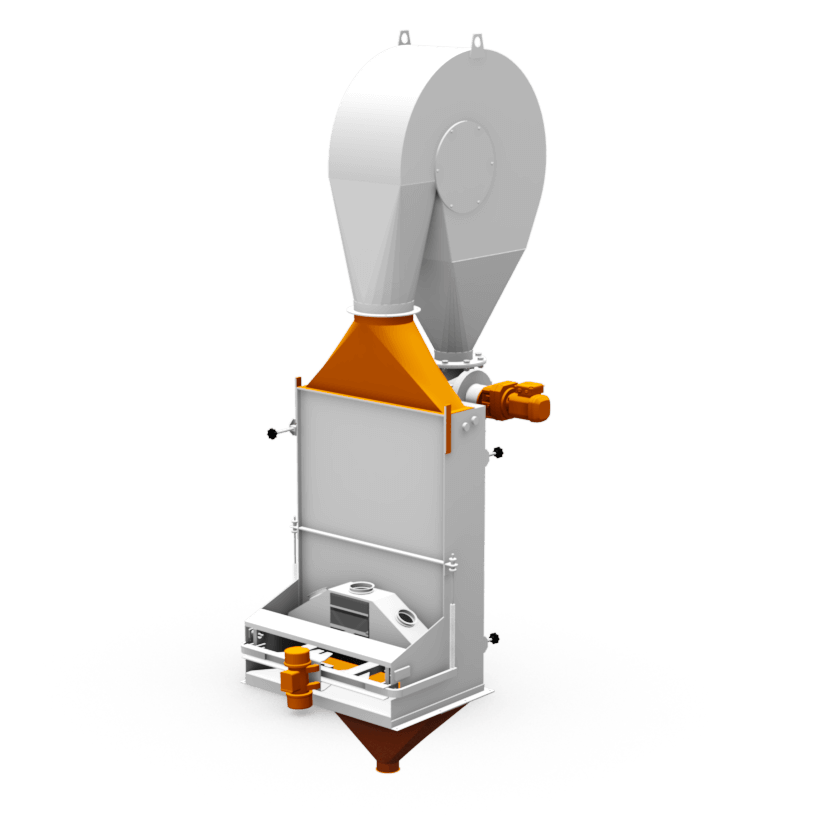

Airleg separator type STS

Airborne vertical cleaning

The airleg separator separates what doesn’t belong together. Light particles such as hulls or dust are reliably screened out. In short, it performs cleanly.

Precise separation thanks to large decision-making area

Our airleg separator removes light particles from a product mixture and also serves to aspirate other products. When the grain enters a vertical airleg channel, the upwards-streaming air passes through the resulting product “haze”. Due to the design, we have a very large vertical separation zone. Undesirable substances are extracted via suction and the heavy grain kernels flow downwards and out of the airleg separator.

Efficient feed-in

A vibration motor which sets the conveying equipment vibrating ensures an even distribution of the product to be cleaned over the entire width of the airleg separator. The air speed and current can be regulated highly precisely – thereby selectively allowing hulls and/or light particles to be extracted via suction. The performance of the machine is determined by the volume that needs to be sieved.

At a glance

-

Precise separation threshold between light particles and product via vertical decision-making zone

-

Accurate control via inclination of the inspection window and adjustment of the integrated throttle valve

-

Available with parts in contact with product made of stainless steel, or in full stainless steel version

-

Suitable for the following grains: Rice, oats, millet, buckwheat, peas, barley

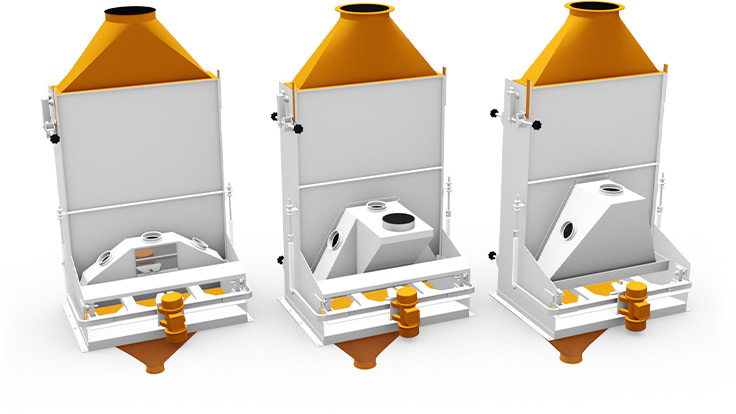

But that's not all the airleg separator can do for you

The airleg separator is frequently used together with a separator unit. This allows the machine to be used optimally as well as relieves the strain on the filters and pipes. The separators can be supplied in various designs and guarantee optimal control of the aspiration settings by the operator.

Technical data – STS

-

Gewicht

97 kg

122 kg

150 kg

150 kg

135 kg

178 kg

178 kg

178 kg

178 kg

142 kg

156 kg

260 kg

254 kg

306 kg

348 kg -

Antrieb

0.17 kW

0.17 kW

0.17 kW

0.17 kW

0.17 kW

0.17 kW

0.17 kW

0.17 kW

0.17 kW

0 kW

0 kW

0 kW

0.17 kW

0.17 kW

0.17 kW

0.17 kW -

Maße

606 x 1057 x 2150

809 x 1090 x 2200

930 x 1089 x 2440

930 x 1089 x 2440

935 x 1089 x 2140

1134 x 1087 x 2450

1134 x 1087 x 2450

1145 x 1119 x 2450

1145 x 1113 x 2450

1115 x 638 x 2400

1115 x 638 x 2400

1317 x 638 x 2450

1398 x 1184 x 2450

1342 x 1097 x 2450

1634 x 1092 x 2454

1644 x 1089 x 2605

Download data sheet – STS

- 400-S Standard St

- 600-S Standard St

- 800-S Standard St

- 800-S Standard VA

- 800-S short version St

- 1000-S Standard St

- 1000-S Standard VA

- 1000-EN inlet funnel St

- 1000-HE high inlet St

- 1000 without drive St

- 1000 without drive VA

- 1200 without drive St

- 1200-EN inlet funnel St

- 1200-HE high inlet St

- 1500-S Standard St

- 1500-HE high inlet St

Technical data – STS with decanter & sluice

-

Gewicht

341 kg

406 kg

370 kg

406 kg

522 kg

492 kg

546 kg

586 kg -

Antrieb

0.17 / 0.55 kW

0.17 / 0.55 kW

0.55 kW

0.17 / 0.55 kW

0.17 / 0.75 kW

0.17 / 0.75 kW

0.17 / 0.75 kW

0.17 / 0.75 kW -

Maße

1064 x 1505 x 3410

1164 x 1756 x 3818

1179 x 1305 x 3768

1176 x 1756 x 3818

1331 x 1739 x 3818

1346 x 1757 x 3818

1634 x 1753 x 3822

1647 x 1757 x 3973

Download data sheet for STS with decanter & sluice

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an