Process

Hulling process

The process steps

-

Grain dehulling

-

Hull separation

-

Grain processing

-

Hull resorting

-

Pre-selection

-

Kernel separation

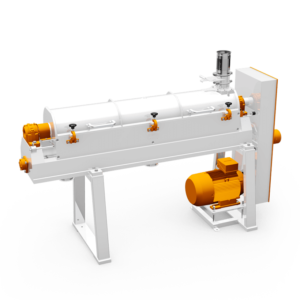

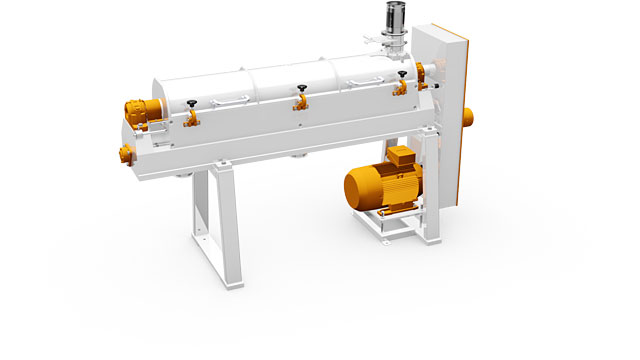

Impact dehuller type GG1

Grain dehulling

The product to be hulled is led through the inlet into the impeller and distributed evenly onto the ejection canals, aligned and flung at the impact ring in a targeted fashion. The hulling performance is determined by the inlet regulator and rotational speed.

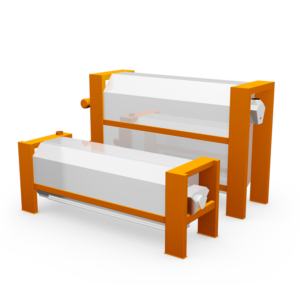

Airleg separator with decanter and sluice

Hull separation

In the airleg channel, the upwards-streaming air passes through the resulting product “haze” from the grain. Here, the hulls and hull parts, which have a lighter specific weight, are pulled upwards. In this step, the primary volume of hulls is separated out.

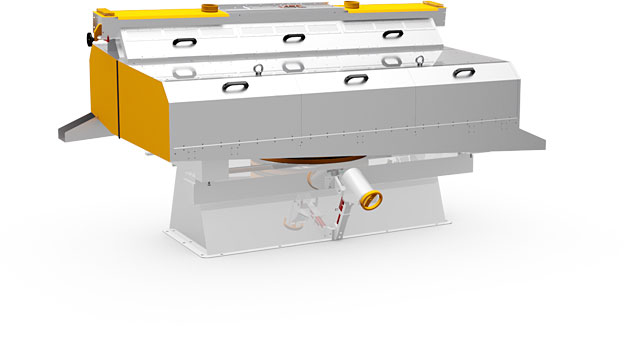

Deawner type Nordmark

Grain processing

The grain is transported to the working chamber for polishing. Adjustable beaters as well as an emery coating on the inside of the roof ensure gentle processing, during which the oat kernels must be completely freed of all tiny hairs and contaminants on the surface.

Airleg separator with decanter and sluice

Hull resorting

Renewed separation of the hulls remaining after the hulling procedure as well as the fine particles generated in the deawner via aspiration.

Indent cylinder type ETA

Pre-selection

The indent cylinder classifies grains according to the length, thereby distinguishing between hulled and unhulled oats. The rotating indent cylinder shell consists of two half shells, which bear tear-shaped embossings.

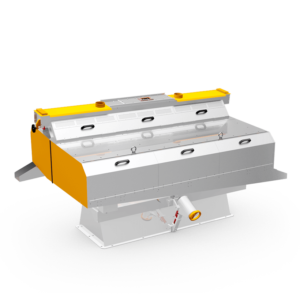

Paddy table type HTA

Kernel separation

For resorting – after the hulling process – the grain to be sorted is distributed to the chambers of the machine evenly. Uniform lifting motions separate the kernels according to their specific weight.